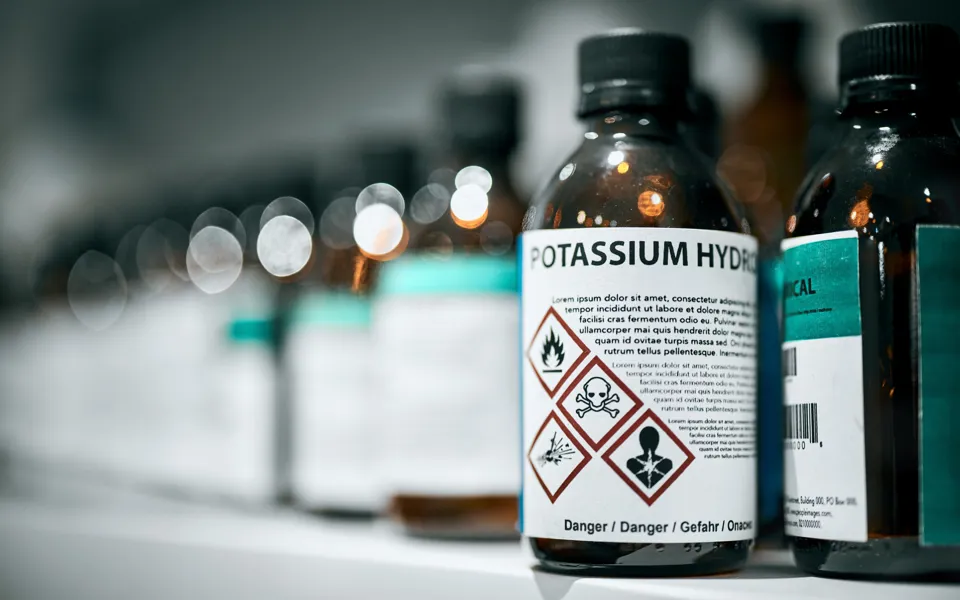

Compliance with regulations such as REACH and CLP is generally seen as the responsibility of chemical companies placing products on the market. Companies that rebrand products may assume the responsibilities have been completed by their upstream suppliers, meaning they only need to copy the information on the labels and SDS from their upstream supplier and put their own name and contact details on it instead.

The regulations do include provisions such as CLP Article 4(6) which states that downstream users can simply use the classification derived by their upstream suppliers as long as they do not change the composition of the product.

But is it really this easy?

Below are a few things that rebranders should check on their labels and SDS to help ensure that they remain compliant with regulations.

Document Language

Labels and SDS are required to be provided in the official language(s) of the countries where the product is being placed on the market. Therefore, if you are marketing in countries other than your own, you will likely need translations of your SDS and labels. However, simple translations of your supplier SDS may not be sufficient. Some countries, such as Germany, have specific additional information requirements that must be included on SDS.

Ricardo offer an outsourced service that can prepare country specific, compliant versions of your SDS.

Poison Centre Notifications & UFI codes

Mixtures classified as hazardous for either physical hazards or health hazards (i.e., those with a label including hazard statements with codes H2xx or H3xx) must be notified to the appropriate appointed bodies in the EU and a Unique formula identifier or UFI code included on the product label for consumer and professional products, or on the SDS for industrial products.

Relying on a Poison Centre Notification from an upstream supplier

Rebranders may use the UFI code provided by their supplier as long as they make no changes to the composition of the product. If the rebrander is changing the trade name and/or the packaging, the rebrander could ask their supplier to update their poison centre notification (PCN) to include this information. They should also check that the supplier’s poison centre notification covers all countries where the rebrander is placing on the market.

If the supplier does not want to do this, rebranders will need to submit their own notification and use their own UFI on their labels and SDS.

Protecting confidentiality

Rebranders may also not want to use their supplier’s UFI to protect their own confidentiality in cases where they don’t want the supplier to know what they are doing with the product, or they don’t want customers to realise it is the same product as their supplier’s product.

In this case they can submit their own poison centre notification for the product and use their own UFI code on labels and SDS.

Ricardo can prepare your PCN dossiers and submit them on your behalf. Many poison centres also have additional requirements such as payment of fees, or annual tonnage reporting. Ricardo can take care of these additional requirements for you.

Classification and labelling

Although CLP Article 4(6) provides that downstream users such as rebranders can use their supplier’s classifications provided they make no changes to the composition of the product, this does not mean rebranders should just copy the classification and labelling from the supplier’s product. There are a few points that a rebrander should consider:

Duty of care

Although CLP says that you can use the supplier’s classification, rebranders do still have a duty of care to ensure that the information is correct. If a supplier’s classification is not correct, it should not be used and the supplier should be contacted to raise the point of concern.

If the product is coming from outside of the EU/UK, there is a good chance that the EU/UK classification may be different to the country of origin due to differences in the implementation of the Globally Harmonised System (GHS) in different jurisdictions around the world.

Precautionary or P statements

A “P statement” in the context of chemicals refers to a Precautionary Statement. These are part of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which provides standardised phrases that describe measures to minimise or prevent adverse effects of a chemical. These statements are essential for the safe handling, storage, and disposal of hazardous chemicals and are included on labels and safety data sheets to communicate the necessary precautions to users.

If changing the packaging, e.g. dividing into smaller containers, or if selling to a different market, e.g. consumers instead of industrial/professional users, a different selection of P statements may be more appropriate. Particularly if changing use to sell to consumers, you may wish to include P statements such as P102 (Keep out of reach of children).

For products sold to the general public, it is a requirement to include a P statement on disposal unless one is not required or it is clear that the disposal of the product does not present a hazard to health or the environment.

Packaging and label design

If changing use of a product from industrial/professional to consumer uses, additional packaging design requirements may be needed, such as the use of tactile warning devices or child resistant closures.

Ricardo will check the product classifications as part of a label and/or SDS check and provide advice on label design and packaging requirements.

Contact us today for a free, no-obligation discussion of requirements >

Follow Ricardo Chemical Solutions for regular updates

Follow Ricardo Chemical Solutions for regular updates