Alumotor: the environmentally efficient e-motor solution

Stuart Bradley, Head of PEMD – Technical Authority at Ricardo, explains how the Alumotor solution is creating an environmentally friendly option for light commercial and off-highway vehicle propulsion.

The UK-Alumotor consortium is being led by Ricardo with Aspire Engineering, Brandauer, Warwick Manufacturing Group, Phoenix Scientific and Global Technologies Racing, to develop a supply chain around an innovative design of an electric motor. The clue is very much in the name, it’s made of aluminium and it’s a motor, offering a low cost, robust and sustainable electrical machine, ideal for the LCV and Off-Highway market.

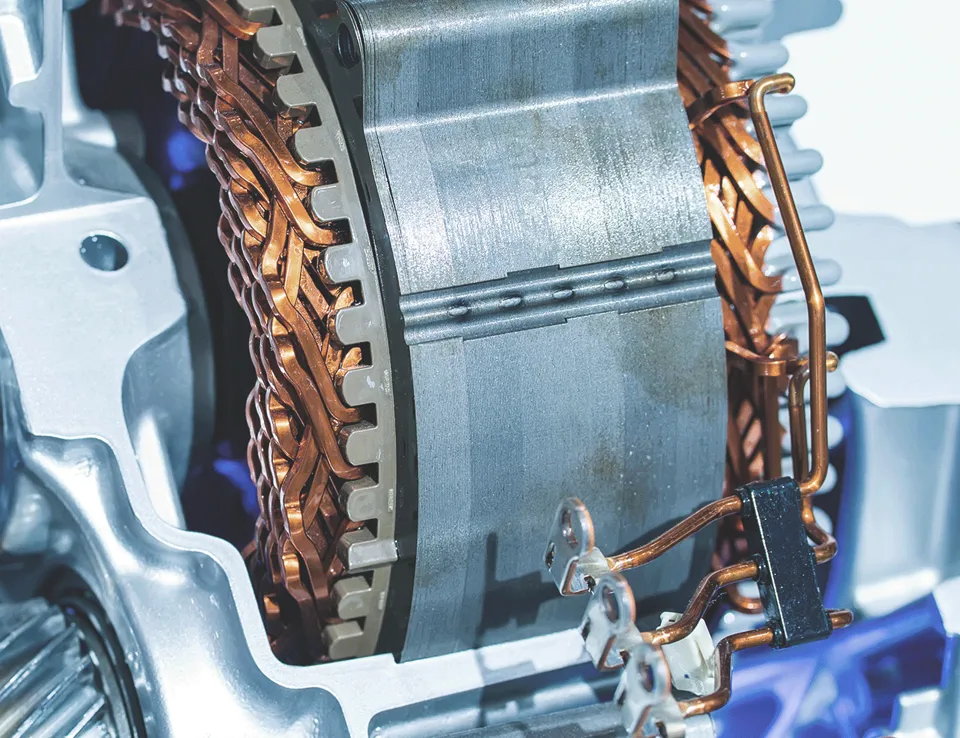

Free from rare earth element magnets, the Alumotor design mitigates the risk of low efficiency and low power density. Taking the principles of sustainability, and replacing copper with aluminium windings, Alumotor is a simple, efficient, and robust synchronous reluctance motor.

The rotor has no windings, but instead uses air-filled channels in the standard version and flux barriers in the high-performance version. Two power ratings are available. An 80-kW version and 100 kW high-performance version with a peak power of 150 kW. Both versions perform well against targets set by the US Department of Energy and the Advanced Propulsion Centre (APC) roadmaps.

The APC UK helps accelerate the transition to a net-zero automotive industry, by collaborating with UK government, the automotive industry and academia to accelerate the industrialisation of technologies, supporting the transition to deliver to net-zero emission vehicles.

The compact packaging of the standard Alumotor means that it’s easy to integrate with an EV transmission and inverter, with a high operating speed and a shared oil cooled thermal system. Typical applications are for the light commercial vehicle market, including 3.5 tonne vehicles. It’s also suitable for off-highway vehicle, such as construction equipment, articulated dump trucks and crop sprayers, where robustness and low cost are both critical and there’s less of a focus on extreme weight reduction and performance.

By comparison, the high-performance variate of Alumotor is likely to have permanent magnets of some sort, although they will not be rare earth, but ferrites. This will potentially be called a hybrid reluctance motor, as it uses both reluctance torque and magnetic torque – boosting performance characteristics.

A significant amount of system know-how has been built into the Alumotor design. It offers a sustainable and environmentally acceptable design using proven materials and methods in the manufacturing process. Advancements in both concept and design phases means that Alumotor is low cost and highly robust, utilising advanced manufacturing processes for the lowest possible cost of quality.

The development of the Alumotor concept and detailed design has been supported by Driving the Electric Revolution challenge at UK Research and Innovation.