Eliminating the carbon footprint of biomass and Energy from Waste (EfW) plants without compromising efficiency

The application of both carbon capture and district heating to biomass and energy from waste (EfW) plants offers great potential for removing carbon dioxide from the atmosphere without compromising energy efficiency.

The role of negative emissions in reaching net zero

The Intergovernmental Panel on Climate Change (IPCC) Report in 2018 laid bare the extent of action needed to limit global temperature rise to 1.5°C above pre-industrial levels. As well as rapid cuts to emissions, the removal of CO2 from the atmosphere is essential in most pathways considered in the IPCC report. As such, negative emission technologies (NETs) such as bioenergy with carbon capture and storage (BECCS), direct air capture (DAC) and biochar, as well as nature-based CO2 removals (e.g. afforestation, enhanced weathering, and ocean mineralisation) are expected to be a necessary part of the solution to halting temperature rise. Since the publication of the IPCC report, many national governments have set net zero targets, now covering around three-quarters of global GDP. NETs are necessary to allow net zero targets to be achieved, as they help balance the residual emissions from hard-to-decarbonise sectors such as aviation and construction.

What is BECCS?

BECCS refers to a suite of technologies which include biomass combustion, gasification, pyrolysis, and fermentation with the resulting CO2 captured and stored permanently. The application of CCS to biomass processes in the power (including CHP) and industrial (e.g. cement) sectors and for hydrogen production could lead to negative emissions if the CO2 is permanently stored. Most EfW plants with carbon capture also have potential to be classed as BECCS processes as a significant proposition of the waste feedstock is biogenic in origin.

The UK is one of the few nations to have pledged dedicated targets for deployment of BECCS, with a capacity of 5 Mt/year CO2 reduction being targeted by 2030. BECCS has the greatest potential amongst NETs to achieve net zero targets due to its technological maturity and lower costs.

In fact, the Department for Business, Energy & Industrial Strategy (BEIS) has recently made an announcement adopting Ricardo’s BIOCCUS as one of the projects to benefit from government funding. This project aims to design, build and test an innovative biomass pyrolysis based cogeneration system with biochar production and carbon capture, utilisation and storage (BIOCCUS) to enable highly significant, practical and scalable GGR systems to help progression towards net zero carbon. The BIOCCUS system uses forestry waste to create biochar, CO2, electricity and heat.

What are the main challenges to implementing BECCS?

The extent to which BECCS plants can deliver negative emissions depends on how sustainable the biomass source is. Unsustainable resources involving energy-intensive cultivation, processing and transport operations will significantly increase life cycle emissions and consequently diminish the benefit that BECCS can offer as a negative emission technology. For wastes comprising a mix of biogenic and non-biogenic material (e.g. plastics), the extent of negative emissions will depend on the composition, but the life cycle emissions associated with the biogenic fraction are generally low.

Another important issue is the reduction of the efficiency of an existing biomass or EfW plant because of the energy penalty associated with retrofitting it with carbon capture. This can be a significant barrier for commercial reasons, and can limit the negative emissions potential.

Consequently, there are two important areas of focus when it comes to BECCS plants:

- First there needs to be full evaluation of the life cycle emissions when estimating the negative emission potential for BECCS.

- There also needs to be full assessment of process integration and heat recovery options from within the CO2 capture and compression plant itself to help reduce the impact of the energy penalty associated with the CO2 capture plant.

EfW plants can play a key role in achieving negative emission targets because of the potential to retrofit carbon capture, converting what is currently a significant emitter of CO2 to a carbon negative BECCS plant. The remainder of this article sets out how this can be done, and how the downsides can be mitigated via for the recovery of heat from the CO2 capture and compression process.

Watch the video: The role of BECCS in delivering negative emissions from biomass-based cogeneration and district heating

The combination of BECCS with cogeneration EfW plants and district heating offers a wide range of benefits including improved efficiency and potential for achieving negative emissions as well as waste treatment. Find out more in this webinar recording.

Like all parts of the economy, the EfW sector must decarbonise in the coming decades

Modern EfW combustion plants are a reliable and effective means of dealing with non-recyclable waste with lower overall greenhouse gas (GHG) emissions than the main alternative - landfill. Nonetheless, EfW facilities still emit considerable CO2, and emissions have grown as the number of UK plants has increased in the last two decades. UK emissions from EfW are expected to plateau at around 5 to 6 Mt CO2 per year. A proportion of this is biogenic, but a substantial fraction is fossil derived (mostly from plastics in the waste stream) with overall net emissions in the region of 2 to 3 Mt CO2 per year. However, capturing and storing a high proportion of this CO2 would reverse the situation, resulting in the EfW fleet actively removing CO2 from in the atmosphere.

Doing nothing is not a viable option in the long term

In the long term, decarbonisation is unlikely to be optional. Operators and owners who fail to act ultimately risk exposure to higher costs associated with carbon pricing and (potentially) missing out on the sales of negative emissions. Other risks include the continually tightening regulation around CO2 emissions and investor pressure driven by the increasing importance of Environmental, Social and Governance (ESG) factors. A combination of these factors could lead to a decline in the competitiveness of unabated EfW.

As such, it is important that operators and owners understand the potential for their plants to decarbonise, even if implementation of such measures may not immediately happen in the short term.

What can be done?

There are three ways in which the carbon footprint of an EfW combustion process can be reduced or eliminated entirely:

- Improving efficiency - via heat recovery and integration

- Capturing CO2 - from flue gas

- Decarbonising the feedstock - by reducing plastic content

The first two options are applicable to the EfW plant itself and are the focus of this article. All three methods above can be combined, and the greater the extent that they are implemented, the better the outcome from a GHG perspective.

Let’s look at each of these measures in turn:

1. Improving efficiency – heat recovery

Improving efficiency helps to reduce the overall GHG impact by displacing additional fossil fuels (such as gas boilers in the case of heat).

The majority of UK EfW plants – including many considered ‘state-of-the-art’ – are relatively inefficient. In most cases, heat from the combustion of waste is used to generate electricity at modest efficiencies of around 25%. The remaining heat is rejected to the atmosphere and so the overall thermal efficiency is low.

There is generally limited scope to improve electrical efficiency in an economically viable manner, with only small incremental gains possible particularly for existing plants. However, large quantities of heat are available which can be harnessed to heat buildings via heat networks. Normally, this is done by extracting low grade steam from the steam turbine to produce hot water, which can be distributed long distances with low losses via insulated pipework. A huge increase in overall efficiency is possible when heat is recovered as well as electricity (from around 25% to over 70% where sufficient demand for heat exists). There are a number of established examples of EfW combined heat and power (CHP) schemes such as those in Nottingham and Sheffield, but these remain the exception rather than the norm in the UK.

Many other facilities have potential to export heat to nearby public and private consumers via new heat networks, particularly in relatively new plants where steam turbines are required to be ‘CHP-ready’ with suitable extraction ports available in the steam turbine.

District heating is a mature technology with low technical risk. The barriers to wider implementation in the UK have generally been commercial rather than technical. However, this is changing as the decarbonisation of heat becomes more pressing. Heat networks are a key element of a net zero compatible heat system as set out in the Heat and Buildings Strategy. Significant funding is available under the Green Heat Network Fund. There are therefore strong drivers to develop heat networks fuelled by surplus heat from EfW plants, and considering the current dramatic increases in gas prices and concerns around fuel poverty and security of supply, heat networks using locally-generated, stable feedstock look increasingly attractive.

Whilst improving efficiency reduces the overall operational carbon footprint, it cannot eliminate it entirely or lead to negative emissions. For this, it is necessary to capture the CO2 emitted from the stack.

2. Capturing CO2

Carbon Capture, Utilisation and Storage (CCUS) involves separating the CO2 from the flue gas in power plants or industrial processes, compressing it onsite and transporting it (for example, either via dedicated CO2 pipeline or by ships) to another location where it can either be used in industrial manufacturing or stored in saline aquifers or oil and gas fields where it is expected to remain permanently trapped:

- Carbon Capture = CO2 separated from clean flue gas, conditioned and compressed or liquified

- Utilisation = usage in industry, agriculture or as input to a process

- Storage = permanent geological storage

Only systems where CO2 is sequestered over long timescales will have an impact on mitigating the climate change impact, e.g. where the CO2 it is stored in geological formations or used in applications such as concrete curing or in the production of aggregates or other chemicals/products where it remains trapped for a long time (for example, in manufacturing of sodium bicarbonate, see Carbon Capture & Utilisation | www.tatachemicalseurope.com) . Alternative uses such as for greenhouses or food and drink manufacturing may have some benefits due to displacement of fossil fuel usage, but ultimately result in the CO2 being released to atmosphere.

Implementing CCUS

As decarbonisation becomes ever more urgent, CCS has emerged as a critical solution to abate CO2 emissions from EfW processes. EfW is particularly well-suited to carbon capture because:

- it is hard to decarbonise by other means,

- it is well-suited technically

- it has potential for negative emissions owing to the biogenic content of the waste

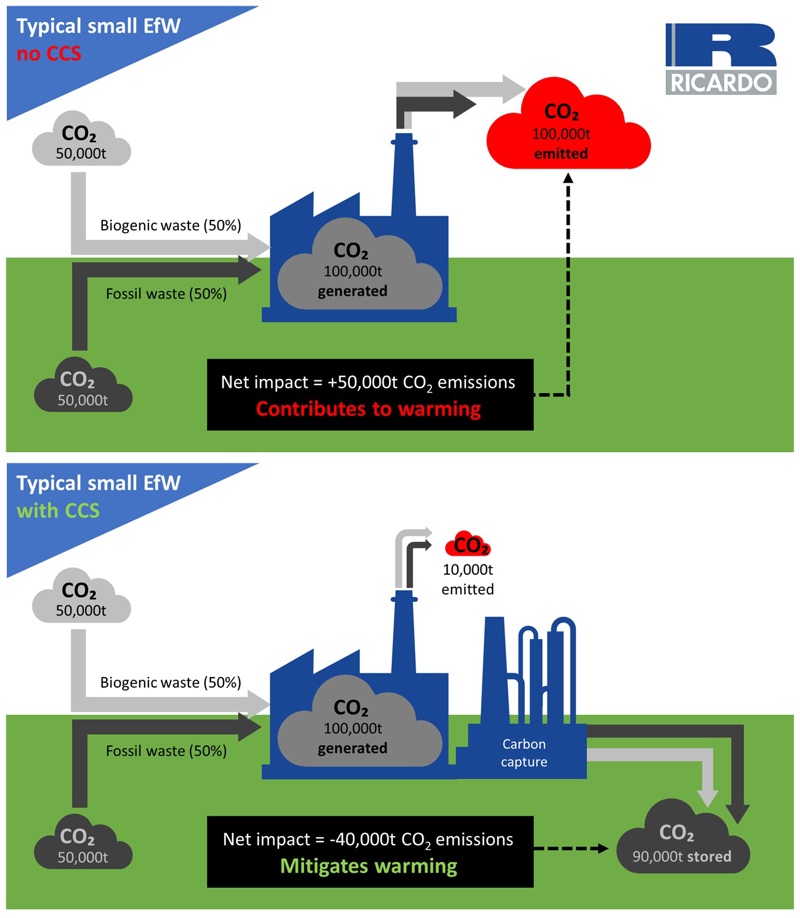

An example of how the retrofit of CCS can turn an EfW plant from a significant CO2 emitter into a BECCS plant drawing CO2 from the atmosphere is shown below. This is a simplified depiction which assumes a capture efficiency of 90%; in practice there are some life cycle emissions associated with both the biogenic and fossil fractions.

A potentially lucrative opportunity?

It should be noted that there is a potentially lucrative opportunity for operators of EfW CCS plants in the future given the importance of removing CO2 from the atmosphere to achieve net zero; markets for the trade of negative CO2 emissions are not established yet but are expected to evolve in time, and this is something which EfW with CCS plants are ideally suited to take advantage of. This could lead to negative emissions having significant value in future which is not yet recognised or factored into the economic case.

However, the main downside to installing CCS is the substantial reduction in efficiency due to the energy consumption of the process, which can negatively impact the economic case and limit the overall CO2 performance. This downside is not inevitable though, as we discuss below.

Combining carbon capture and heat offtake

Carbon capture requires substantial quantities of steam and/or electricity which reduces the steam available for generating electricity. For an electricity-only plant, there is therefore a significant energy penalty associated with carbon capture. Previous Ricardo analysis shows that a reduction in electrical output of at least 25-35% can be expected from an amine-based carbon capture process when applied to power generation plants.

However, much of the heat within the CO2 capture and compression plant can be recovered in the form of low-grade heat (hot water rather than steam). This can be utilised for district heating purposes, with a heat pump used to upgrade the heat if required. Several BECCS projects are being developed across the EU which aim to utilise the heat from the CO2 capture plan for district heating. Examples are the Stockholm Exergi biomass CHP plant in Sweden and the Fortum Oslo Varme’s EfW plant in Norway, both at an advanced stage of planning.

The best of both worlds – carbon capture without the energy penalty

EfW plants which export both power and heat (CHP) are good candidates to be fitted with CO₂ capture as, while they generate electricity, they also produce the heat which can be used by the capture plant. Combining carbon capture and heat export minimises losses as heat can flow both ways; from the CHP plant into the CO2 capture plant for solvent regeneration and can also be recovered from within the CO2 capture process and fed into a district heating system leading to significant efficiency improvements over an electricity-only plant. Our previous analysis shows that, with optimised heat integration of a CHP plant with CO2 capture, the energy penalty can potentially be reduced from a loss of 25-35% (for power-only plants) to below 5% for large biomass CHP sites with district heating.

The amount and grade of heat which can be recovered from the CO2 capture plant will depend on the type of CO2 capture system installed but is typically low-grade heat which can be fed into a district heating network.

In summary

- Installing CO2 capture overs great potential to convert an EfW plant from a process that emits CO2 to a proposes that (indirectly) removes CO2 from the atmosphere (i.e. a form of BECCS)

- Despite the huge benefits it brings, CO2 capture can significantly reduce the efficiency of plants that generate electricity due to the demand for steam and/or electricity

- The recovery of heat from the CO2 capture process can substantially offset the loss of electrical output, resulting in minimal negative impact on the overall thermal efficiency.

- The development of a new (or expansion of an existing) heat network provides an outlet for low grade heat from the carbon capture process – heat which is carbon negative!

- Both carbon capture and implementation of district heating are critical elements of the UK government’s approach to achieving net zero by 2050. EfW plants with carbon capture and connected to district heating are likely to be futureproofed and may be highly competitive; able to sell heat, electricity and, in the long term, able to take advantage of the value of negative emissions.

Introducing BIOCCUS

Our heat and power demonstrator plant, BIOCCUS, showcases a realistic carbon negative technology that can significantly contribute to net zero targets due to its applicability to several energy-intensive industry sectors as an on-site generator of heat and power.

Learn more >

Contact us for support

If you’re considering implementing changes in your plant and would like expert support, please contact us.