Is your packaging sustainable and compliant with legislation (and for how long)?

Your packaging must be both sustainable and compliant to be fit for market in today’s world. Ricardo sustainable packaging expert, Nicole Costantini, explains why truly sustainable packaging is designed on circular economy principles but underpinned by an understanding of the evolving legislative landscape.

Sustainability is a buzzword across most sectors, and this is particularly the case within the packaging industry. With increased pressure from not only “green conscious” consumers and investors but also from constantly evolving compliance legislation across the globe, the environmental impact of packaging is rising to the top of producers’ agendas particularly in markets that are heavy users of packaging such as food and drink, chemicals manufacture and automotive supply chains.

Producers who are not taking action to improve the sustainability of their packaging will be falling behind the market and soon pay a higher cost if they fail to keep on top of new legal requirements.

One of the most common questions asked by manufacturers to Ricardo’s dedicated sustainable packaging team is:

“How do I really make my packaging more sustainable for the future and what is the first step?”

Some sustainable packaging advances come in the form of reactionary changes sparked by legislation, such as the incorporation of recycled content with the introduction of the UK’s Plastic Packaging Tax. As an individual action this change is positive. However, even taking a brief look into regulatory changes on the horizon e.g., the introduction of Extended Producer Responsibility (EPR) in the UK it becomes clear that this type of packaging improvement will only ‘tick the box’ for so long.

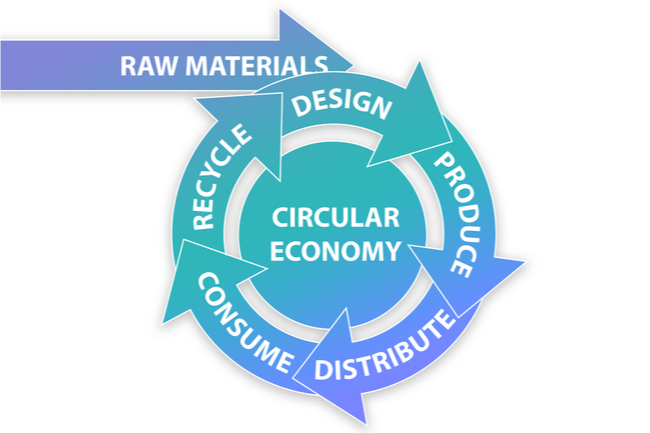

To produce truly sustainable packaging, with the lowest environmental impact, existing and foreseeable future regulatory requirements must be fully understood and then the broader environmental impact and circularity of the material needs to be considered at the design inception phase. In other words, the design of the packaging must be built around a circular economy model which takes into account all parts of the materials’ life cycle.

Your packaging is not truly sustainable if it is not designed with current and future compliance in mind.

When addressing a topic as broad as sustainable packaging, the first step is to address legal compliance with the existing packaging regulations. As mentioned, legislation is a key driver for much of the change within the packaging industry, not just in the UK but globally.

Packaging compliance systems were first born in the EU as the result of the Waste Framework Directive, with many other areas following on such as waste electrical and electronic equipment (EEE) and batteries. The success of these systems in diverting waste from landfill have inspired other nations around the world to adopt similar legislation, with over 50 countries worldwide now boasting Extended Producer Responsibility legislation or similar regulations. Challenges do arise with the varying requirements across these territories but the importance of compliance, given its direct links to potential fines and legal prosecution, is undeniable.

In first assessing their legal obligations and understanding the regulatory landscape; both current and future requirements that are under consultation, a producer will have a better understanding of the requirements affecting their business and can take these into account at the design phase alongside best practice guidelines not yet outlined in legislation.

Once you have understood the legislative landscape for your markets and have this underpinning your strategy, you can progress to designing your packaging in line with a circular economy model by thinking about end of life right at the very start of the process.

“A circular economy is one in which stuff is kept in use for as long as possible, delivering the highest value it can, for as long as it can” (Ellen Macarthur Foundation).

“A circular economy is one in which stuff is kept in use for as long as possible, delivering the highest value it can, for as long as it can” (Ellen Macarthur Foundation).

A key element of the circular economy is the waste hierarchy, which prioritises the prevention of waste, with disposal being the final option. We are seeing an increase in circular economy legislation, with the UK Government, amongst others across the world, beginning to introduce legislation and regulations that are in line with this hierarchy.

Key examples of this type of holistic view range from ways of increasing recyclability, where possible, to designing packaging with the intention of re-use, such as refillable containers. This could involve anything from avoiding unnecessary laminations and films to prevent hindering the recycling process, through to developing intuitive ways to break down packaging into its constituent parts, design using only one type of material or a single polymer or re-designing the product delivery process entirely, i.e. by designing packaging suitable for re-use systems. Whilst re-use has long been part of the waste hierarchy, is still not a concept that is widely adopted due to the logistical challenges and there is much work needed to make re-use easier across the entire packaging value chain.

Key examples of this type of holistic view range from ways of increasing recyclability, where possible, to designing packaging with the intention of re-use, such as refillable containers. This could involve anything from avoiding unnecessary laminations and films to prevent hindering the recycling process, through to developing intuitive ways to break down packaging into its constituent parts, design using only one type of material or a single polymer or re-designing the product delivery process entirely, i.e. by designing packaging suitable for re-use systems. Whilst re-use has long been part of the waste hierarchy, is still not a concept that is widely adopted due to the logistical challenges and there is much work needed to make re-use easier across the entire packaging value chain.

Of course, to increase the sustainability further, aspects such as the carbon footprint of the packaging must also be reviewed, for example by undertaking a full life cycle assessment (LCA).

Where LCA’s are considered, typically the focus is on paying for and undertaking these in-depth calculations geared towards the product itself. However, to meet organisational climate goals and to effectively tackle supply chain (Scope 3 emissions) both product and packaging portfolios must be assessed to deliver the required carbon reductions.

Most packaging producers agree with these circular economy principals and the benefits of acting upon them, however stumbling blocks often arise at the implementation stage. Common barriers include identifying priorities, cost, access to baseline datasets to measure progress against and all this whilst crucially ensuring the packaging is still desirable and fit for purpose. Ultimately, packaging needs to protect the product it contains, this is true from both the commercial and environmental perspectives as it’s the product inside that will usually contain the highest embodied carbon so must be saved from waste through damage.

For companies wanting to simply mitigate costs and those wanting to lead the way in sustainable packaging, having a deep understanding of both the global legislative landscape and how to apply circular economy principles is critical to the development of a robust roadmap that will help break down the various requirements into manageable actions, whilst driving continuous improvement and helping businesses to remain competitive in two areas that are rapidly evolving: packaging innovations and sustainability.

Ricardo’s team of packaging experts can conduct regulatory compliance assessments on your existing stock to help you understand what you must change now and for the future. Through their deep understanding of the current and upcoming legislative landscape and experience in applying circular economy principals, our experts can help you to develop a robust forward-looking packaging strategy and roadmap, enabling you to implement truly sustainable and effective packaging that satisfies consumers, investors, and legislators as well as your own commercial needs.

Get in touch to chat about how Ricardo’s packaging team can support your sustainability journey.