Making EVs better performing, safer and cheaper

01 Feb 2021

Ricardo is part of a collaborative R&D consortium which has received funding from Innovate UK and the Faraday Institute to work on an innovative immersion cooling battery technology which looks set to revolutionise the electrified transport sector. The technology has won The Engineer’s Collaborate to Innovate award 2020 for Automotive. Here, we speak with Ricardo’s Head of R&D, Richard Gordon, and Global Technical Expert for Thermal Systems and R&D fuel cell leader, Dr Cedric Rouaud, for the inside track on this game-changing technology.

Q: Can you give us details of the project for which you have been nominated?

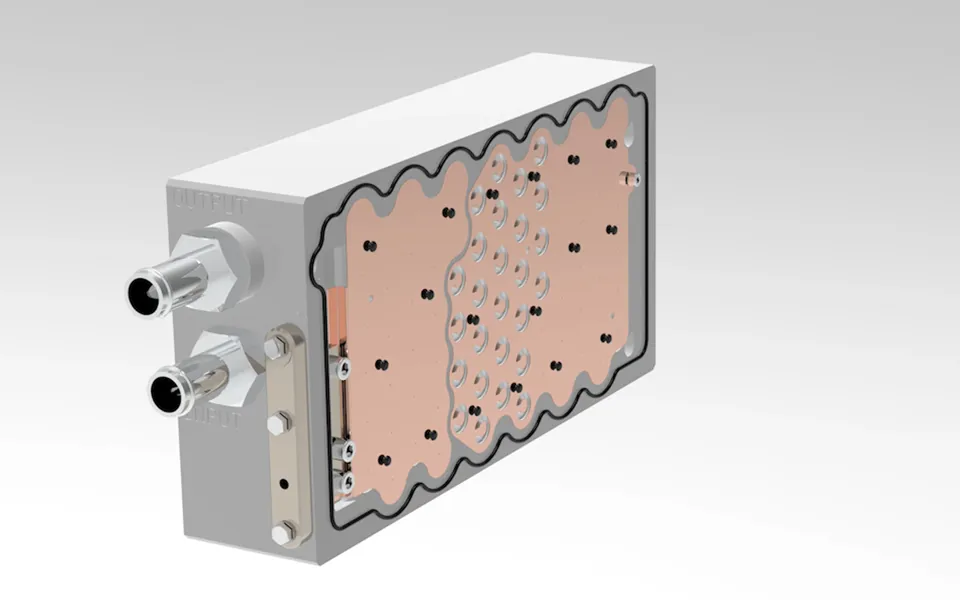

Cedric Rouaud: Ricardo is part of a consortium with M&I Materials Ltd and Warwick Manufacturing Group at the University of Warwick working on an 18-month research project research funded by Innovate UK and the Faraday Institute. The project is about investigating the potential benefits of innovative immersion cooling battery technology. We developed two battery solutions: one

a conventional cold plate cooled battery, and other using the same battery but immersion cooled to our novel design. Our purpose was to simulate and test the comparison of the cooling performance of the conventional cooling system versus the immersion cooled solution, and also the benefits of immersion cooling in terms of thermal runway mitigation and battery ageing.

Richard Gordon: This is part of a combined grant-funded opportunity. We are exceptionally grateful to have received this funding and to work with the excellent partners to deliver such a fantastic project. We very much hope all of the partners and the outreach they are doing finds success from the project, and that it helps progress the Government’s message of electrification, which is something Ricardo wholeheartedly supports through all of our strategic and tactical endeavours.

Q: How does the immersion cooling battery technology work and what benefits does it offer?

Cedric Rouaud: Ricardo has developed a proprietary design and assembled modules for the immersion cooled battery. It was tested by M&I Materials and Warwick Manufacturing Group during the project. The technology is focused on immersion cooling using the concept of partial immersion cooling, limiting the amount of liquid needed to improve cooling performance under high charge and discharge rates of operation.

The technology offers four key benefits: better performance, lightweight, lower cost and improved safety.

- Better performance

For battery electric vehicles, the better performance will be seen during charging at ultra-fast charging rates, meaning that (cell allowing) we can recharge a battery pack in less than eight minutes from 10% to 80% state of charge. For HEVs, it means that we can operate at very high rates of charge and discharge, finding diverse application in motorsport, more conventional hybrid systems for passenger cars and also in commercial vehicles and off-highway machines.

- Lightweight

It’s really important that we have designed a technology which is also lightweight, because we can improve the weight of the battery pack versus a conventional cold plate solution thanks to our partial immersion cooling of the cells and the bus bars. Because of this lightweight aspect, the technology can easily be used in the aerospace industry, and indeed, the Ricardo proprietary design approach of partial immersion cooling is currently being used in the propulsion module for the next generation electric aircraft we are helping to develop with consortium partners for the InCEPTion project which is co-funded by the UK’s Aerospace Technology Institute and Innovate UK.

- Lower cost

We can reduce the total cost of the battery and the impact on the vehicle by using immersion cooling, thanks to the lower cost of the battery pack. This is achieved by having a simpler cooling method which removes expensive materials used inside the battery pack such as within the cold plate and thermal interface materials, which are currently used in conventional cooling methods.

- Improved safety

We have also improved safety. For thermal runway, there are legislation and safety aspects. When we develop electric components, we always have in mind the safety of the occupants, OEMs and tier one suppliers. Using immersion cooling can mitigate and stop thermal runway and fire propagation. Current solutions, of course, are fully compliant with legislation and stringent regulations on safety. As vehicles continue to evolve in terms of efficiency and performance, we all work hard to make future vehicles even safer for drivers and passengers and reflect the legislation and regulations which will inevitably evolve as vehicles develop.

We have developed a solution which offers quicker charging, is cheaper to produce, and offers safety enhancements.

Q: Can the technology be applied across other sectors?

Richard Gordon: The cross-sector applicability of Ricardo’s R&D has always been important for us to maximise the leverage we can achieve from our investments. We have to find innovations and technology solutions which can be used across multiple sectors.

Our innovative immersion cooling battery technology is a great example of this. It’s about making batteries safer - which pretty much every application of a battery required – but also have very good performance in a small package volume. A lot of sectors have that need, whether that is a high performance vehicle, such as a supercar, or vertical take-off and landing aviation (VTOL) applications, or to fit within very tight package volumes in industrial machinery. In each case, our innovative immersion cooling battery technology can offer significant advantages.

Because of the way it reduces the temperature difference between cells during charging and discharging, it can also improve the life of the battery through reducing ageing hotspots within the pack. So, the longevity and robustness of the battery pack as a whole is improved. That finds strong interest in critical applications such as defence and also high value asset such as large, expensive off-highway machines and on-highway trucks, that have very long lifetime expectations to achieve good total cost of ownership.

Our innovative immersion cooling battery technology superbly meets cross-sector need: motorsport, defence, on-highway, off-highway, aviation, and there are probably other applications as well which we haven’t explored yet – in the marine sector for example. It has a great future ahead of it I’m sure, and I’m proud of what the project team and partners have achieved.

Q: What unique value does Ricardo add to this project and how does it fit into Ricardo’s world-renowned R&D portfolio?

Richard Gordon: Ricardo has a long and distinguished track record in research and development.

We have been delivering R&D successfully for over 100 years across a very wide variety of topics. Twenty years ago, Ricardo recognised the need to move into the electrification space. We developed tools and techniques, grew great teams, built hybrid and electric vehicles and learned from the experience of delivering projects internally and for our customers.

More recently, it’s become apparent that the battery is one of the most challenging areas to engineer in a way that is cost-effective, safe, provides the right performance and life expectancy and is competitive in the fast moving arena of hybrid and electric vehicles. Over the last five years, we’ve been investing heavily in the battery space with a wide suite of R&D projects. Our innovative immersion cooling battery technology fits in this portfolio perfectly, offering very high performance and very safe battery pack design solutions.

Our immersion cooling battery technology is one of many R&D projects in the battery space. We have found a way of applying immersion cooling pragmatically: it’s a lightweight solution that manages the battery thermal needs at very high-performance levels. It’s a very impressive step up in how immersion cooling is applied. In addition, we have developed the simulation tools around it, and this is something that resonates across all of our R&D projects. There is a very strong desire to design and develop the innovation on the desktop right first time, so when we come to manufacture prototypes they are highly likely to work first time and to specification. This virtual development, especially for innovations, is an important part of improving R&D efficiency. This project in innovative immersion cooling battery technology has helped us move the core technology forward, but also how we apply it to our customer projects using these virtual tools. Already, thanks to these outputs and learning, we have won customer projects and further research opportunities built around this technology.

Cross sector application is another thing which sets Ricardo apart in deploying our research outputs, because we do have such a wide sector reach within our business areas. It is often part of our customers’ request. Our Hi-Fi Elements toolchain allows us to develop battery packs across many domains that have challenging battery pack requirements in approximately half the time it would traditionally take. We are also looking at connected battery management systems (BMS) to improve the efficiency of batteries in fleets of vehicles: passenger cars and on-highway light commercial vehicles and trucks, and we are also seeing application in large-scale energy storage systems for grid balancing or renewable energy storage, where we can connect up these systems whether it is an array of large battery systems or multiple sites geographically. This connected BMS is a great way of looking at how we optimise battery packs for long lifetime and performance throughout their main service life and for second life applications.

We are highly cross sector focused across the digital domain. For example, as part of the European Union’s research and innovation programme Horizon 2020, the Thomson project developed tools to support a quick transition towards highly efficient, cleaner and more affordable electrified powertrains to then stimulate consumer uptake in order to meet global emissions targets and legislation.

Within the Thomson project, Ricardo developed an integrated toolchain for electrified vehicle powertrains enabling simultaneous optimisation of hybrid, engine and aftertreatment calibration. The multi-domain simulation toolchain builds on Ricardo’s integrated model based development (IMBD) capabilities to enables hardware evaluation for different solutions, quickly facilitating rapid selection of optimum solutions within specified design constraints whilst minimising CO2. It can be applied to almost anything that has flows of energy and different domains with different challenges, be that thermal, electrical or control, or also some of the vehicle challenges like drag, friction, inertia and so on. We apply such toolchains pretty much across every sector we work in.

Outside of specific R&D in the battery space, we are also working in fuel cell control systems - for example looking at the balance of plant development to optimise weight in relation to cost and efficiency – and investigating how their applicability to opportunities in rail, stationary power, on-road vehicles and off-road machinery.

Q: What benefits can your innovative immersion cooling battery technology offer for consumers?

Cedric Rouaud: Immersion cooling fits in very well with our electrification strategy, particularly focused on highly sustainable vehicles and powertrains, because it helps to enhance the uptake of electric vehicles in the next four to five years. Immersion cooling is enabling ultra-fast charging for electric vehicles.

Currently, one of the fastest charging electric vehicles is the Porsche Taycan, which takes 23 minutes to charge, offering a significant improvement over more mainstream offerings. As such capabilities trickle down to mass production vehicles, the uptake of EVs will be encouraged. With our immersion cooling battery technology and cell allowing, people who do not have access to a plug at home can go to a filling station and recharge in less than eight minutes. And we are focusing on improving that to get to a charge time closer to six minutes. Although we have not worked on the cell technology during the project, we are working on the cooling technology which enables the cell to operate safely during that ultra-fast charge. Without immersion approaches, we cannot recharge so quickly. We would have to extend the duration of the recharging to 12-15 minutes. In that scenario, it’s beginning to be a rest break, and not an ultra-fast charge. That is still an issue for some buyers.

Richard Gordon: In addition to Cedric’s points, the immersion cooling battery technology delivers the benefit of improved battery lifetime, so removing the risk of, which can be a worry for some buyers of electric vehicles. It promotes a reliable, long-term investment and helps them enjoy the product. It also gives excellent performance so it will have a competitive advantage compared to vehicles without the immersion cooling technology. So, we are adding tangible value to those end customers.

Through having significantly better cell thermal management, we can deliver better battery efficiency in the vehicle system which leads to better vehicle range for a given pack capacity. We deliver this range improvement by far more intelligent integration of the battery pack thermal system into the vehicle. We can then manage the thermal needs throughout the electric powertrain and electronic systems as well as the cabin needs and so deliver further range improvements. Furthermore, this approach lends itself very well to being connected to the cloud and using off-vehicle information to further optimise energy over the complete journey. This is something we have demonstrated recently in our ConnectHEV vehicle and are developing further in our connected battery management system project now.

We want to encourage the further natural adoption of electric vehicles by significantly enhancing their performance and utility so they are attractive to consumers. If we can deliver amazing products people will adopt them because they get enjoyment from them and value their performance and incredible functionality. OEMs are now offering high compelling products and that is starting to resonate with consumers. EV range is steadily improving, meeting many more consumers’ requirements, and the infrastructure is building around us, so it’s a great time for electrification to be embraced and to grow strongly. Our innovative immersion cooling technology for EV batteries is a very powerful building block to help improve the cost and performance ratio and hence wider acceptance.

Q: What does the award nomination mean for you?

Cedric Rouaud: The nomination highlights the thought leadership that Ricardo has in the development of energy storage solutions, which will be widespread in the coming years, and beginning to be the principal solution for the passenger car. For other broader automotive sectors – like commercial vehicles or off-highway – there are other additional solutions, such as hydrogen, but for the passenger car applications, battery power will be the mainstream. So, having developed this immersion cooling battery technology well ahead of our competitors and tier one suppliers, the nomination of this award helps us show global OEMs how Ricardo is able to invent and forge new ground in developing sustainable and impactful solutions addressing their major needs.

Richard Gordon: This nomination is highly motivating for all our employees and excellent partners who have worked very hard to bid and deliver this project successfully. It’s great for their efforts to be recognised in this way. If we win, that is further confirmation that we have chosen the right content within the project, that we have delivered it with excellence and that it is finding appreciation within the industry for it to be game-changing. That’s very much what we try to achieve in our R&D areas. We want our R&D output to make a difference. We provide exceptional levels of expertise in delivering leading edge and innovative cross sector sustainable products and solutions, helping our global customers increase efficiencies, achieve growth and create a clear and safer future. Our mission is clear – to create a world fit for the future. The nomination is strongly motivating to our whole team to do more and take Ricardo further in the electrification space.

Being nominated for this prestigious award also helps us to get noticed by wider areas within our customer base whom we would like to get to know better. It also helps us to connect with new customers, perhaps in new market segments, for whom our R&D outputs may help solve their complex challenges.

It will also help us reach out to the younger engineers in our business, bringing vividly to their attention what impact their work can achieve here, and so encourage them to be part of our R&D activities if they haven’t considered it before. It all helps to spread the good word of what R&D can deliver, and so that recognition would be very much appreciated by all of us at Ricardo and I’m sure by our partners also.

Find out more about our recent work on immersion cooled battery technology in our latest case study: iCoBat Consortium | Immersion cooling technology case study.

Follow Ricardo plc for regular updates

Follow Ricardo plc for regular updates