Play Video

Ricardo’s in-house manufacturing capability explained

20 Feb 2024

Ricardo is well known for our world-class engineering expertise in the automotive and industrial industries, but did you know that we also have in-house manufacturing capability to support your engineering programme?

For over 50 years, we have provided our low-volume precision manufacturing services to some of the most recognisable OEMs and tiered suppliers in top-tier motorsport, high-performance automotive, aerospace, defence, and industrial markets.

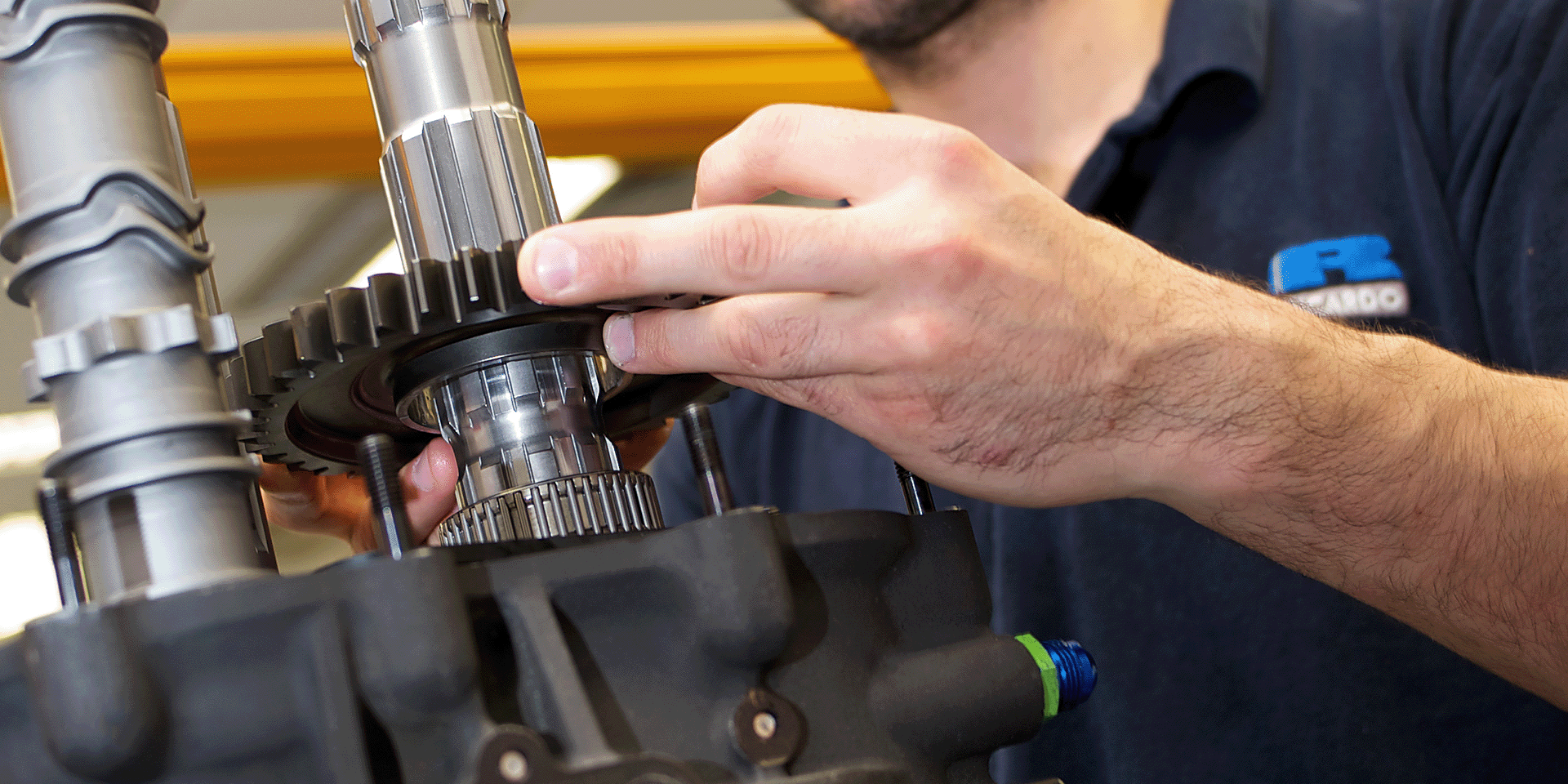

Primarily, we provide design, low-volume manufacturing and series supply of complex components found in engines and drivelines, from complete transmissions down to sub-assemblies and parts, such as precision gears and prismatic machined parts.

Our manufacturing programmes are tailored to the requirements of our clients, but our typical services include:

- Turnkey transmission design, manufacture, and supply

- Component design, manufacture, and supply

- Prototype design and manufacturing

- Re-manufacturing solutions

- Low-volume contract manufacturing and outsource manufacturing solutions for driveline and powertrain components and sub-assemblies

Manufacturing for high-performance and specialised applications

We specialise in creating bespoke precision manufacturing solutions for platforms with high performance and specialised applications.

What do we mean by that? Well, our experts are world-leaders in supporting programmes requiring stable series supply of critical components delivered in compressed lead-times which have complex operational and performance requirements or which must align to strict regulatory standards.

In top-tier motorsport, for example, we are globally recognised for our custom transmission solutions which has given our clients the winning edge in their race series. From the highly regulated Formula 1 to the World Rally Championship where peak performance and endurance are paramount to success. All of which must be delivered on-time and in full to meet race schedules.

Learn more about how we've helped our motorsports clients

For our clients in the high-performance automotive and sports car markets, we provide precision quality and performance engines and drivelines matched to the premium product expectations of their customer base.

As an AS9100D-certified supplier, our customers in the aerospace industry rely on Ricardo for stable supply of durable and reliable precision components for platforms.

And in the defence market, we apply our specialist manufacturing knowledge to refurbishment and reengineering programmes to keep their vehicles in service for longer.

Low volume manufacturing capability

We focus on markets and applications which require supply of highly specialised torque path or specialised prismatic components delivered in low and niche volumes. This means a specialised approach to the way we operate our manufacturing programmes.

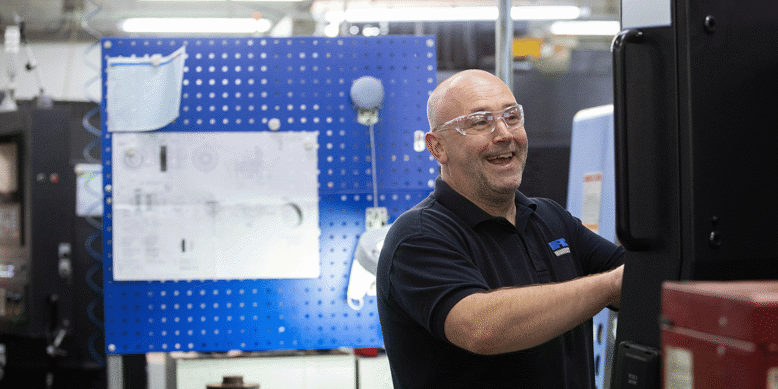

With decades of industry knowledge, our team of specialists are the cornerstone of our precision manufacturing capability. They apply their expertise across the whole production cycle to tailor solutions to the unique requirements of each programme.

From the design phase, where design for manufacture and value engineering principles help to ensure that the product is built with cost-effective manufacture in mind. To supply chain selection and management, where they work closely with our clients to source materials matched to the programme’s exact performance, regulatory, weighting and cost requirements.

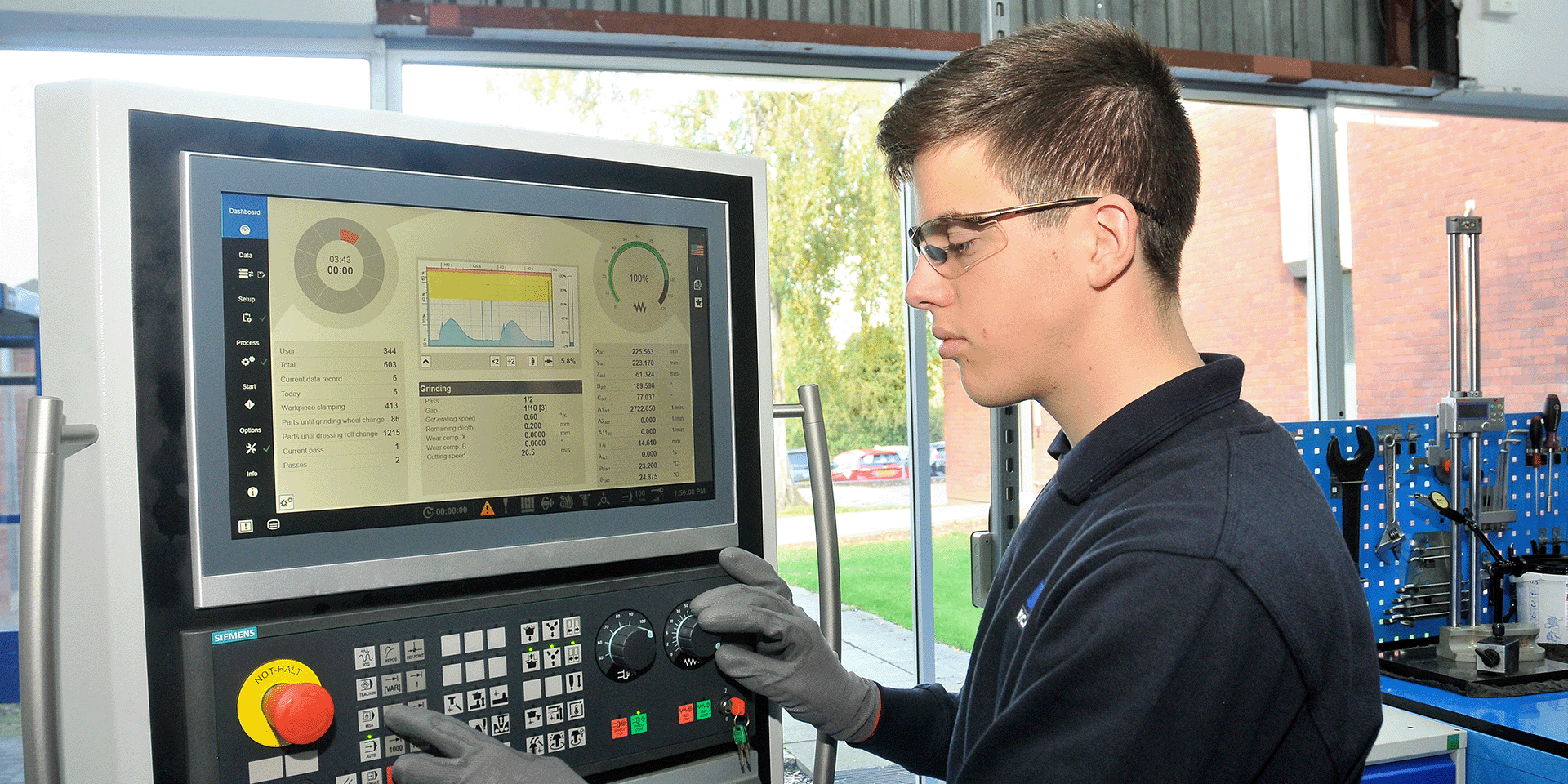

Our skilled machining experts operate from our state-of-the-art facility which hosts multi-axis CNC machinery and advanced conventional tools. This enables the manufacture of precision gears, torque path and prismatic components with complex geometries, tight tolerances, and intricate features. All whilst adhering to Ricardo’s strict quality management processes to ensure delivery of components which meet industry regulations and the quality and performance requirements of our customer.

Here is an example of our in-house machining capability:

- CNC and conventional turning machines, with vertical and horizontal capability

- CNC and conventional milling machines with vertical, horizontal and multi-axis capability

- CNC and conventional milling with internal, external, surface and jig capability

- CNC and conventional prismatic machining

- CNC and conventional gear cutting tools - hobbing, shaping chamfering and deburring

- CNC and conventional gear grinding - external straight, helical and bevel capability, and internal straight and helical capability

- EDM capability - wire eroding and spark eroding

- Heat treatment capability

- Inspection and quality including CMM capability and in-house metallurgical laboratory

Why choose Ricardo as your niche volume supply partner?

What sets Ricardo apart is not just the cutting-edge technology that we use in our manufacturing processes, but the unwavering commitment to excellence and attention to detail exhibited by our manufacturing experts.

The team takes pride in their ability to consistently deliver programmes which tackle the toughest engineering, manufacturing, and supply challenges for our clients in these specialised markets.

Whether they are designing and manufacturing from a clean sheet for a series supply transmission programme, or they are delivering batch orders of complex components to an existing design, our clients can expect exceptional attention to detail and a premium product which match and exceed expectations.

Our truly end-to-end capability across the full product development cycle, from design to in-service spares and warranty provision means that we can reduce the risk to business-critical powertrain and driveline development programmes where reliability, performance, durability, and quality are essential to the success of the product.

With a history grounded in expertise and a forward-looking approach, Ricardo continues to be the partner of choice for full-service development programmes for high performance and specialised applications.

Ready to start your manufacturing journey?