PanMon

Introducing PanMon

PanMon is a remote condition monitoring system that provides accurate measurements of damage on the pantograph units of passing trains as they undertake everyday operations.

Installed at key locations along routes, the PanMon technology continuously captures images and measurements from the trains without causing any interruption to passenger or freight services.

Infrastructure asset managers can then assess the condition of each individual pantograph unit in operation on the network and collaborate with vehicle owners to prevent defective units from inflicting damage to overhead wires.

- Carbon surface shape

- Dangerous cracks and chips

- Thickness of remaining carbon

- Pantograph uplift

- Pantograph symmetry (pitch, yaw, roll)

- Horn presence or damage

- The scanner also captures regular images for manual visual inspection

Improved track availability: PanMon allows immediate action to be taken to prevent dewirements and ensure track availability and safety.

Real time insights: Information is continuously captured and analysed. Automated comparison analysis raises alarms when thresholds are breached.

Cost reduction: Preventing dewirements and extending the asset life of both wires and onboard pantograph equipment results in significant cost reductions.

Safety: PanMon can help detect component degradation before maintenance limits or safety limits are exceeded, reducing incidents that affect train service.

No software installation: No specialist software installation is required. PanMon's web-based dashboard is accessible via an API and can be integrated into the customer’s systems.

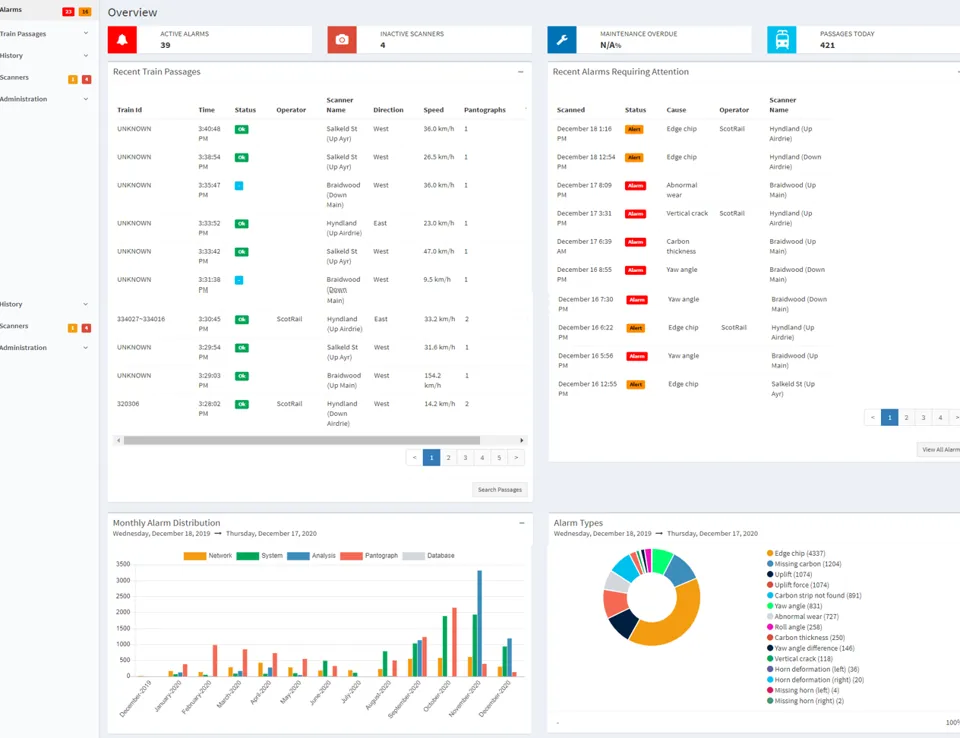

PanMon dashboard

PanMon's main dashboard provides real-time readings from each location and highlights where alarms have been raised. Users can view each individual scan for more specific details.

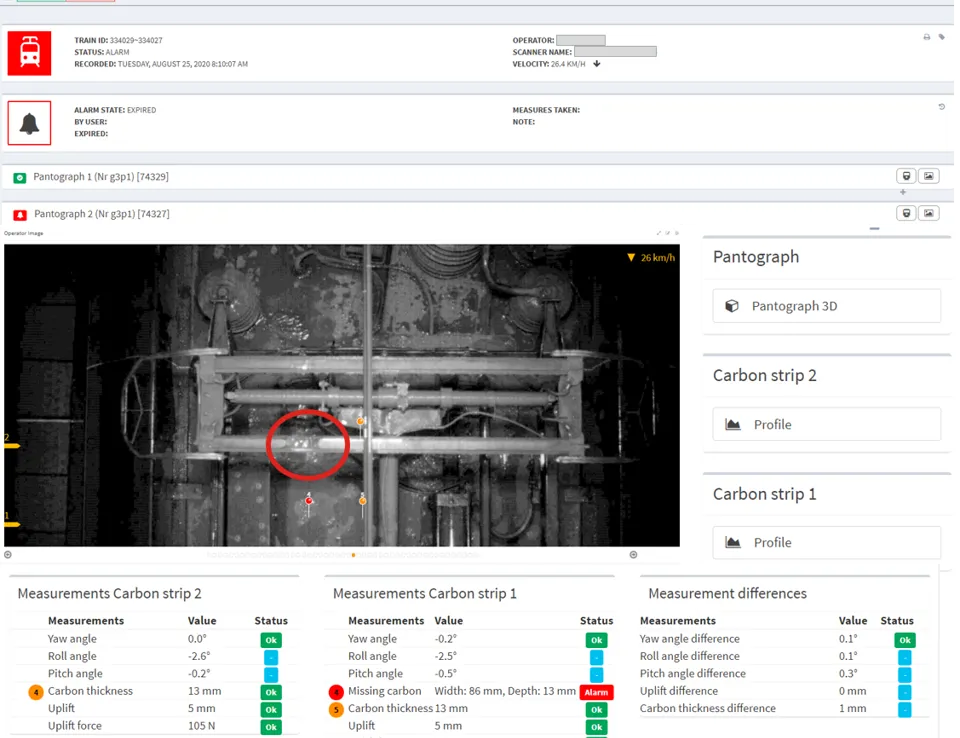

Detailed diagnostics

Clicking an identified alarm on the home page presents operational teams with the photographic evidence alongside a detailed diagnostic report. In the example pictured below, the PanMon scanners have identified a piece of missing carbon (in the red circle) on a passing pantograph unit.

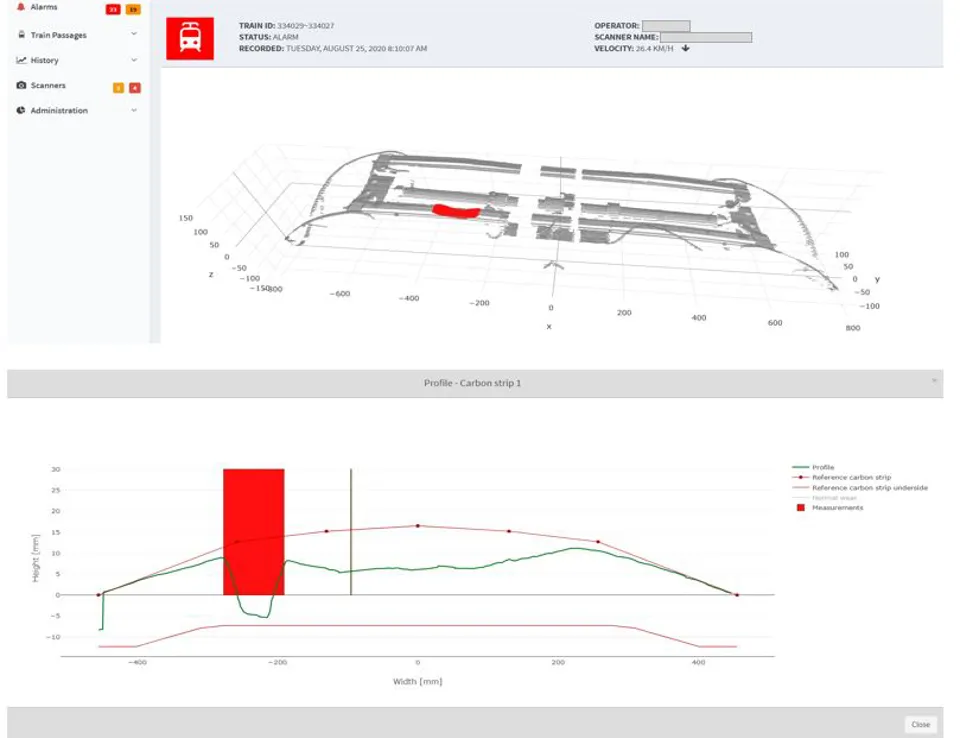

Pinpoint detail of pantograph damage

Operations teams can closely inspect the damage by 'zooming in' on the 3D scan and carbon profile. The carbon profile shows the wear pattern and highlights the damage (in red).

Projects

Pantograph Monitoring on Scotland's rail network

Read project

Pantograph monitoring on Brussels rail routes

Read project

Track geometry assessment with PUPIL

Read project

“These systems have identified damaged pantographs that needed immediate actions to avoid possible overhead wire breaks. ”

Infrabel

Catenary engineer

Why choose PanMon

Precision monitoring

High accuracy in defect detection is achieved by scanning the entire pantograph from a position above the catenary

Quality visuals

2D photo and 3D laser models to enable accuracy of measurement and allow easy recognition of damage.

Reduced costs

Automated, cost-efficient real-time surveillance reduces unplanned maintenance work.

Expert support

Supported by Ricardo's in-depth knowledge of rolling stock and infrastructure maintenance concepts.