Intelligent vehicle lightweighting will be a critical consideration for OEMs on the road to 2035

On the road to 2035 and beyond, OEMs will come under increasing pressure to decarbonise their portfolio across the full product lifecycle. Lightweighting has long been used as a method of improving vehicle efficiency and reducing the environmental impact of a vehicle with a focus on reducing emissions attributed to the use phase. But how does that translate across the full life cycle of the product? It is essential that OEMs make intelligent vehicle lightweighting decisions which take the full product life of the vehicle into consideration, understanding the trade-offs at each stage of the process.

Life cycle assessment of vehicle lightweighting

The most fundamental aspect of intelligent vehicle lightweighting is considering the carbon benefit that lightweighting will have during the use phase and comparing that with the emissions impact of the materials being considered to reduce mass across the full lifecycle of the vehicle.

It’s undisputable that reducing mass improves use phase CO2 emissions of by reducing the amount of energy needed to move the vehicle. It has been a methodology used to reduce fuel consumption for decades. However, when we look beyond the use phase of the product lifecycle, it is not so straight forward.

The production of most materials used to reduce vehicle mass tend to be more energy intensive than the steel that they replace. This can create a trade-off in which the additional emissions created in the production phase can outweigh the use phase CO2 benefits of reducing mass. Many emerging mobility trends will exacerbate this trade-off by reducing the use-phase benefit of mass reduction.

Lightweighting requirements are changing as automotive technology evolves

The future of mobility is changing radically and rapidly. In the next 15 years, we will see increasing adoption of autonomous vehicles and Mobility-as-a-Service models, with accompanying EV and battery efficiency developments.

As a rule, powertrains are becoming more efficient which is contributing to the reduction of use phase CO2 emissions. However, more efficient powertrains benefit less from mass reduction, accentuating the trade-off between use phase and production phase emissions is greatly reduced.

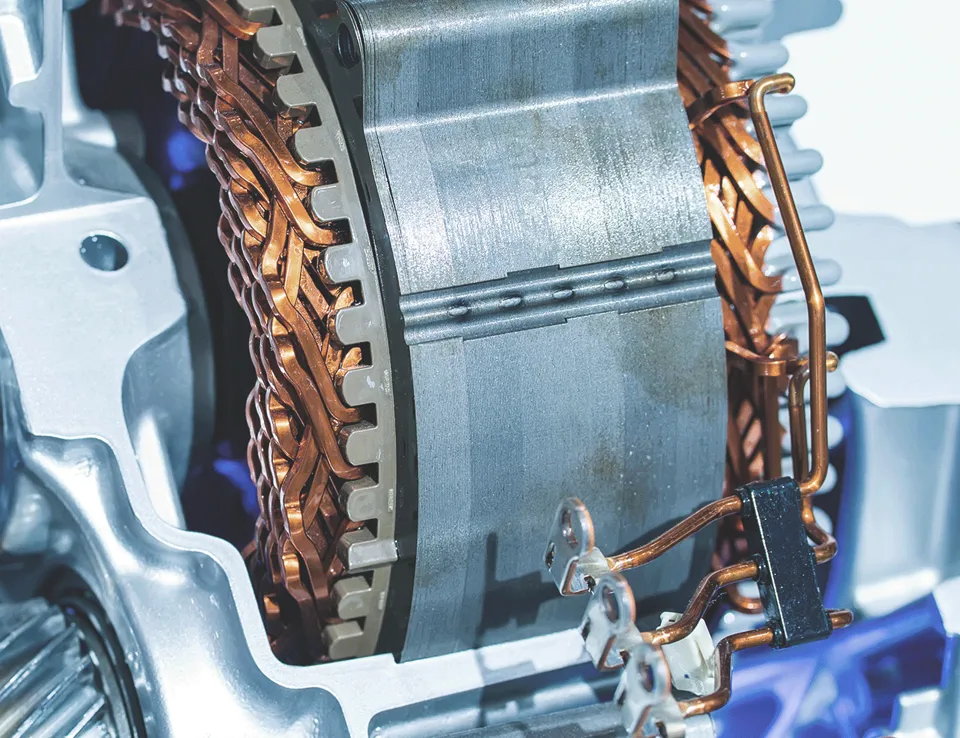

This is particularly evident as we move from fossil fuel to electric propulsion. The much greater efficiency of EVs means that less use phase energy is saved by reducing mass. Additionally, many electric vehicles use regenerative braking systems to recover energy, which makes the power demand even less sensitive to the vehicle’s mass.

There are a few special considerations to be made when considering the lightweighting of electric vehicles. Reducing weight in an EV’s package can enable increased battery capacity to improve range on a single charge. Ultimately though, since mass savings in the vehicle structure are replaced by additional battery mass, there is often little or no net savings in the mass of the vehicle. This means that there will likely be little reduction in CO2 emissions attributed to this lightweighting.

However, when reducing the mass of an EV through lightweighting, the amount of energy it takes to move the vehicle is reduced, and it can be equipped with a smaller battery to achieve the same range goals. A smaller battery means lower battery production emissions, which can help offset the higher production emissions form the lightweighting materials. However, as battery manufacturing becomes more efficient, this offset is reduced – lower production emissions per kg of battery means that saving battery mass saves fewer kg of CO2 emissions, making it harder to offset the higher material production emissions. This further affects the trade-off. The savings that lightweighting using energy-intensive materials could potentially outweigh the emissions savings of a smaller battery.

Finally, as vehicle automation becomes increasingly available as an option for consumers, we will see a fundamental shift in vehicle performance. By smoothing out the vehicle’s accelerate-decelerate cycle, these systems will allow the vehicle to perform at the optimum efficiency for the situation that the vehicle is in. Again, improving vehicle efficiency and further reducing the impact that mass reduction would have on emissions during the use phase.

Lightweighting, the circular economy and the end-of-life phase

When considering the full product lifecycle of a vehicle, it’s important to take the circular economy into consideration. There is a growing focus on the end-of-life of vehicles and recyclability of materials will play an increasingly important role in the production of automotive products.

Using materials in the production phase which can then be recycled when the vehicle reaches the end of its usable life can dramatically reduce its carbon impact. Similarly, using recycled materials can also contribute to the reduction.

Choosing the right materials and methodology will be essential to intelligent lightweighting

Decarbonisation of mobility is going to be heavily reliant on a lifecycle approach to understand the trade-offs between choices made to reduce emissions. Lightweighting in particular must be done intelligently to assure these choices achieve net emissions reductions. ntelligent lightweighting takes many factors into consideration. It will be important for OEMs in the mobility sector to ensure that the CO2 reductions contributed by their lightweighting solutions translate across the whole of the product lifecycle.

Some elements of future vehicle design could reduce environmental impact in some phases of the vehicle’s lifecycle, while increasing impacts in other phases. Taking a life cycle perspective can help minimize these trade-offs, ensuring that the vehicles designed for this new mobility are really doing their share to reduce transport emissions.

The bottom line is that OEMs will need to carefully consider the carbon impact of their whole portfolio in this manner. Choosing the right materials and methodology for their lightweighting strategy be a key contributor achieving the best solution which benefits the consumer, the business, and the environment.

A blog by Russ Balzer LCACP, WorldAutoSteel Technical Director

https://www.worldautosteel.org/

Russ Balzer LCACP, Technical Director WorldAutoSteel and Environmental Consultant, The Phoenix Group

Russ Balzer is an environmental and manufacturing consultant for the Phoenix Group, providing environmental, safety, quality and operations support to the steel industry. Presently, Russ manages the WorldAutoSteel vehicle life cycle assessment (LCA) modeling programs, working closely with stakeholders to improve understanding of the impact of material choices on achieving greenhouse gas reductions objectives.

Russ is involved in several WorldAutoSteel efforts to address the issue of vehicle carbon footprint and life cycle assessment, including his role as delegate to the World Steel Association’s global LCA Experts Group and is a contributor / analyst for automotive mass benchmarking programs.

Education: B.S.S. Environmental Compliance, Ohio University

Affiliations: American Center for Life Cycle Assessment

Certifications: Life Cycle Assessment Certified Professional (LCACP)