Identifying viable options to reduce emissions from aircraft refuelling operations

The Energy Institute, the UK chartered professional membership body for experts who work across the world of energy, commissioned Ricardo to evaluate the potential for GHG emissions reduction from aircraft refuelling operations. The study was produced between 2021 and 2022.

The report sought to identify alternative solutions to mitigate emissions from aircraft refuelling vehicles while providing a comprehensive life cycle assessment (LCA).

Ricardo performed a detailed life-cycle assessment of potential solutions to reduce greenhouse gas (GHG) emissions from aircraft refuelling vehicles, where the largest reduction potential was identified through the replacement of diesel vehicles with fully electric hydrant dispensers and refuellers.

Challenge

While refuelling at an airport gate, the stationary emissions of parked aircrafts can be an important source of emissions at airports. As airport stakeholders seek to decarbonise their ground handling operations, it is important to understand the options available and the true environmental impact of the choices made.

Airports operate with many refuelling vehicles (a major hub could have up to 100), which mostly use diesel fuel and therefore have implications for local air quality and GHG emissions. Since the vehicles are only replaced once every 10-15 years, decisions made now will be felt many years into the future and could jeopardise the operators’ own environmental goals. Using Ricardo’s state-of-the-art LCA modelling capabilities combined with our deep knowledge of existing (and forthcoming) vehicle technologies available in the market, the study provided a detailed assessment of the refuelling equipment technologies that can support reducing emissions associated with aircraft refuelling.

Our approach

The study provided an assessment of technologies such as the latest generation diesel-powered vehicles, engine-off technology for hydrant dispensers, the use of hydrogenated vegetable oil, the deployment of hydrant carts for refuelling narrow-body aircraft, the use of electrically-powered pump off for refuellers, and the adoption of fully electric hydrant dispensers and refuellers.

Given the specificity of the vehicles in question, the study performed an extensive review of the information available on the different refuelling technologies and combined this with extensive interaction with stakeholders, including fuel supplier/into-plane operators and equipment manufacturers. This compensated for the lack of information available on these specific vehicle types. This information fed into Ricardo’s LCA model, which covered all the relevant equipment options used for refuelling worldwide (a total of five different types). The model included life-cycle emissions from the production and use of refuelling vehicles. A case study was developed, which focused on a major European airport, to demonstrate the potential GHG emissions reductions from the different aircraft refuelling options.

The study provided a clear analysis and evaluation of the lifetime GHG emissions benefits of the range of aircraft refuelling equipment technologies available to different types of airports. It considered the use of alternative equipment for refuelling vehicles, such as stop-start and electric pumping, electrically powered zero-emission refuelling vehicles and static refuelling carts, as well as the use of alternative fuels in the current equipment.

Results

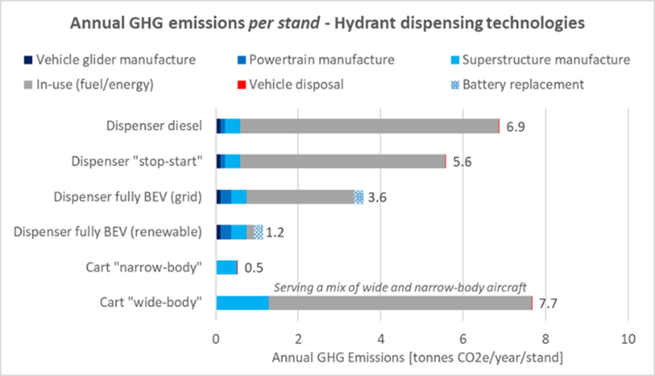

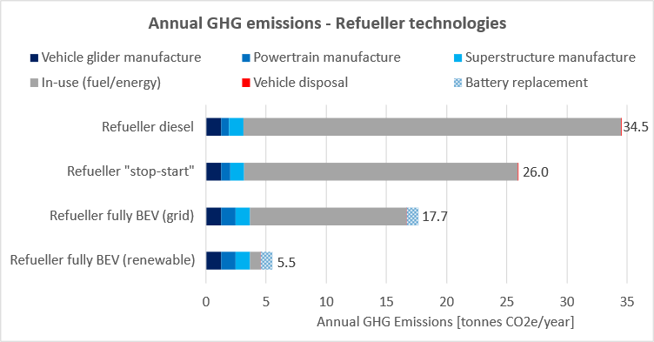

The results of the LCA analyses, summarised in the figure below, showed that hydrant carts without diesel engines have the lowest overall emissions, with a 92% reduction in GHG emissions per year per stand compared to a diesel dispenser. Excluding hydrant carts (which might not be suitable for all types of airport operations), battery electric dispenser trucks offer the next lowest emissions whilst also enabling both narrow- and wide-body planes to be serviced. To maximise carbon reductions, battery electric dispensers should be powered using 100% low-carbon electricity to achieve up to a 83% lifetime reduction compared to diesel dispensers. The reduction is lower when using the average electricity available in the European electrical grid, at 48%. Similarly, battery electric refuellers that use low-carbon electricity have an 84% reduction in emissions compared to diesel refuellers (assuming a single battery replacement is required during the operational life of the refueller).

Battery manufacturing accounts for a much higher proportion of emissions compared to ICE (internal combustion engine) production for diesel vehicles. This is expected to reduce as battery technology improves and manufacturing utilises lower emission energy sources. Although accounted for as part of the LCA, Ricardo’s assessment found this did not significantly affect the findings. If a vehicle were to need a mid-life replacement battery, the overall GHG saving compared to a diesel vehicle would be around 3% lower.

Stop-start technology, which allows engine-off refuelling, is a valuable technology in the short term for both hydrant dispensers (with a 19% lifetime GHG saving over diesel) and refuellers (with a 25% lifetime GHG saving over diesel) when electric vehicles powered by renewable electricity are not yet available.

The Energy Institute reported that the LCA was a very successful piece of work that extended beyond expectations in terms of the detail provided in the analysis and Ricardo’s team’s ability to work with the limited information available.

The results of the study are expected to be valuable to the aircraft refuelling sector, fuel suppliers, airports, and airlines, to inform them of decarbonisation policies and action.

Client quote

“From the proposal to the delivery stage, Ricardo work stood out as being highly professional and competent. The final result went beyond what we were expecting in terms of detail.” Martin Hunnybun, Head of Good Practice - Fuels and Fuel Handling, Energy Institute

Related items: