Immersion cooled battery technology for electric vehicles

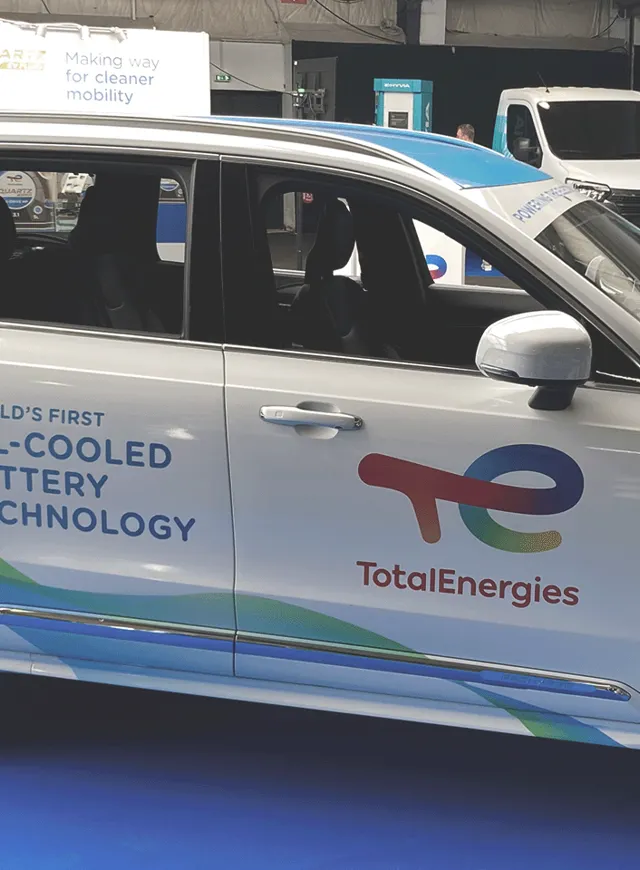

Ricardo partnered with French integrated energy company TotalEnergies to create an immersion-cooled battery technology for electric vehicles. While immersion cooling has been used in niche applications from other vehicle manufacturers, this project represents a world-first mass production vehicle replacing the traditional traction battery cooling system with immersion cooling technology to enhance efficiency, safety and performance while increasing battery life and reducing cost and risk for vehicle OEMs.

Challenge

TotalEnergies appointed Ricardo to support the development of a new immersion-cooled battery technology for electric vehicles.

While immersion cooling has been used in niche applications from other vehicle manufacturers, the project represents a world-first mass production vehicle with the technology.

Approach

Dielectric fluid is used to cool the battery, which permits a higher power capability than the original design. Use of a higher power charge reduces charge time from two hours to less than 30 minutes. This was an important factor in the requirements as expectations for running EVs has changed, with bigger batteries and higher performance, faster charging is essential. The current technology can’t manage the heat generated from bigger cell capacity and the increased power of the charge.

TotalEnergies and Ricardo used a production vehicle – a Volvo XC60 plug-in hybrid – although a wide range of applications are possible. These include static storage systems, trains and off-road applications. Using an SUV made it easier to identify the improvement on a like for like comparison. But all vehicles on the market were benchmarked.

Dielectric immersion cooling will enhance efficiency, safety and performance while increasing battery life and reducing cost and risk for vehicle OEMs.

Ricardo has strong thermal management experience and our approach included simulation and analysis, design and testing to deliver the required thermal benefits. The project fits perfectly with TotalEnergies environmental challenge, using research and innovation to provide a solution with greater durability, better vehicle performance, enhanced battery life and a charging time four-times faster as a conventional liquid solution.

Results

This immersion cooling technology improves battery thermal management, leading to faster charge-times and will make vehicles better performing, safer and cheaper, helping to accelerate adoption of electrified transport with consumers. It replaces the traction battery cooling system with an immersive one, without affecting the vehicle architecture or structure.

In addition, on this project the battery was tested to its limit and proved that this technology can prevent fires breaking out demonstrating that an immersion cooled module delivers superior safety for batteries.

Immersion cooling can also reduce the weight and cost of the car. This battery cost can be reduced by 6% through a simpler design and materials which delivers a saving in weight.

With the project now complete, the technology is being introduced to battery and vehicle manufacturers to show them the advantages of immersion cooling.