Battery assembly and industrialisation

Niche volume battery assembly and industrialisation solutions for high performance and specialised applications.

About our niche volume battery assembly and industrialisation service

As more industries embrace electrification, bespoke battery solutions are becoming increasingly essential. Finding battery packs with the right performance specifications, in the right volume and with the appropriate packaging can be difficult for OEMs in markets such as performance automotive, defence, and off-highway.

OEMs operating in these markets may also require low volume, series production of their products. Therefore, battery production solutions for these markets must match both the niche volume and performance requirements, whilst providing cost-effective quality to meet brand expectations.

To meet this requirement, Ricardo offers specialised battery assembly services to meet the unique needs of our client’s specialist technology. For those clients who would prefer to set up their own battery manufacturing facility, we can provide full-service industrialisation support to get their facility up and running.

News and insights

Niche volume battery manufacture in the UK

Read campaign

Ricardo and InoBat announce new battery module solution at The Battery Show Europe 2024

Read press release

Exploring Ricardo's battery assembly and facility build services

Read insightAssembly programmes for specialised applications

We offer our battery assembly solutions across a range of industries and platforms. Our cross-sector capability enabled us to work with any client requiring a battery solution assembled at niche volume quantities. Applications include motorsports, personal mobility platforms, aerospace, energy storage, and medical equipment.

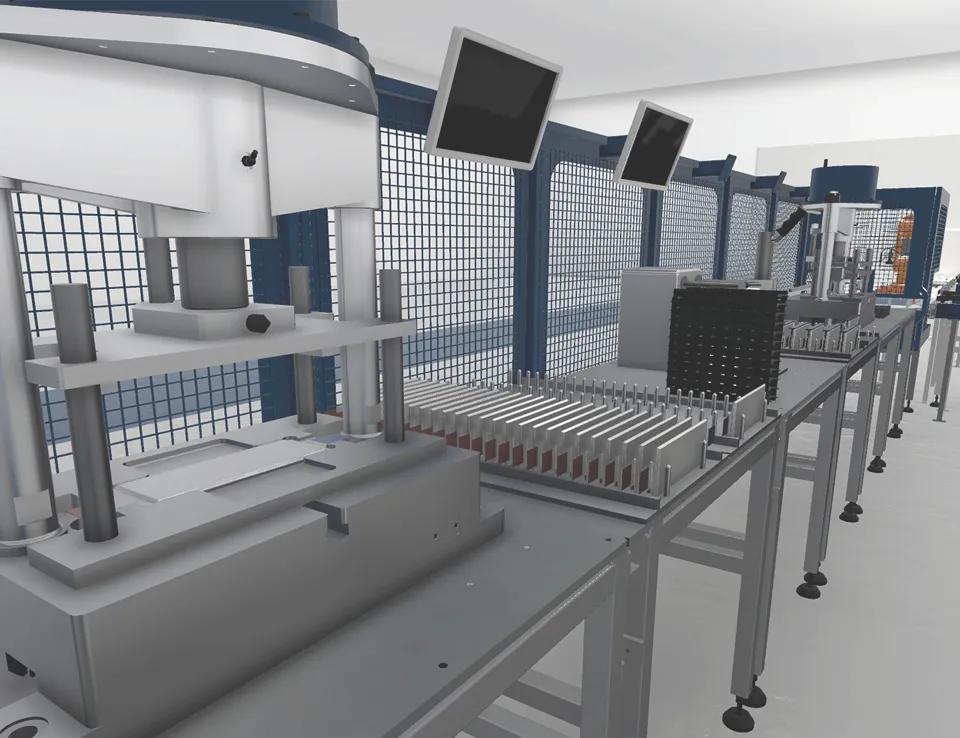

Each programme is assigned a dedicated project team lead to engage with our customer and ensure that their specifications are met. With clearly defined objectives and relevant KPIs put in place, we develop the programme, set up an assembly line, and manage the supply chain with transparency.

We collaborate with our clients from start to finish. This enables us to deliver the programme in an effective and efficient manner, while offering the best value. We have extensive experience in creating electrification solutions for the next generation of mobility. Our battery assembly approach is unique. We are an ideal partner for any client needing a battery solution at low volume quantities.

Battery facility specification

Some clients would prefer to bring their battery pack assembly and manufacturing capability in-house. This involves extensive planning, process implementation and supplier sourcing before the first batteries can roll off the production line.

Ricardo's industrialisation consultants build on our world-class manufacturing and assembly expertise to help get battery production facilities set up for success.

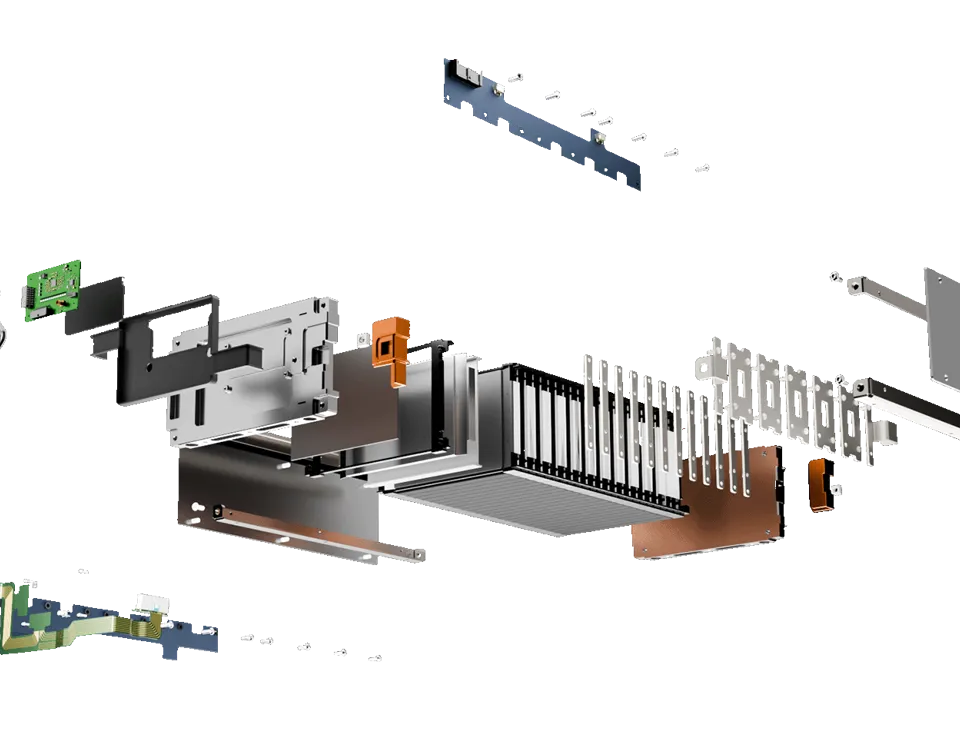

From sourcing of raw materials to design for manufacture (DFM) and design for assembly (DFA). From developing and assembly process to sourcing cell packs. Our team of experts can help with every aspect of setting up your battery factory, from facility specification through to design of manufacturing processes, and on to commissioning.

Our supply chain management specialists can advise on the best approach for the production requirements of our clients. We help businesses build quality assured, sustainable supply chains to support the efficient, high quality and profitable delivery of their products and services.

Make Ricardo your battery assembly partner

Flexible in-house capability

Our battery assembly service is delivered on Ricardo’s niche assembly line. This enables us to be flexible with delivery on volumes based on the changing requirements of our customer, optimising costs and build schedules.

Trusted partners

We work with trusted partners in cell manufacture who provide optimum solutions based on the requirements of our customers.

Niche volume assembly specialists

We specialise in the assembly of low volume, high complexity solutions to the high-performance automotive industry.

End-to-end electrification solutions

Ricardo engineers specialise in the development of end-to-end electrification solutions to the mobility market. We are trusted to deliver full-service programmes from concept through to series production.

Battery assembly and industrialisation Resources

Ricardo employees named in 2024’s The Manufacturer Top 100 list

Read articleThe future of motorsport: Trends, opportunities and challenges to look out for over the next decade

Read articleRacing towards a green future

Read articleDeveloping a Formula E transmission solution for DS Performance

Read articleMeet the experts

Speak to an expert

Can't see this form? Email us here