Batteries and energy storage

Our experts deliver innovative hybrid and electric battery pack solutions. We design, build, and integrate battery technology bespoke to the requirements of our clients.

Battery design, simulation and development testing for a safe and sustainable future

Ricardo has extensive battery engineering, design and development experience in the field of hybrid and electric vehicles. We develop battery pack and energy storage solutions across a range of capabilities ranging from applying new chemistries and formats, to designing and building prototype packs and supporting our clients through full production programmes.

Our whole-vehicle hybrid and electrification design and development experience gives us the contextual insight we need to develop optimum vehicle battery solutions.

Our battery teams utilise the latest tools and techniques to ensure robust design and development and are integrated with our vehicle engineering team to ensure optimal mechanical, structural, and thermal design, maximising volumetric and gravimetric density, be it for a power or energy dense application.

Projects

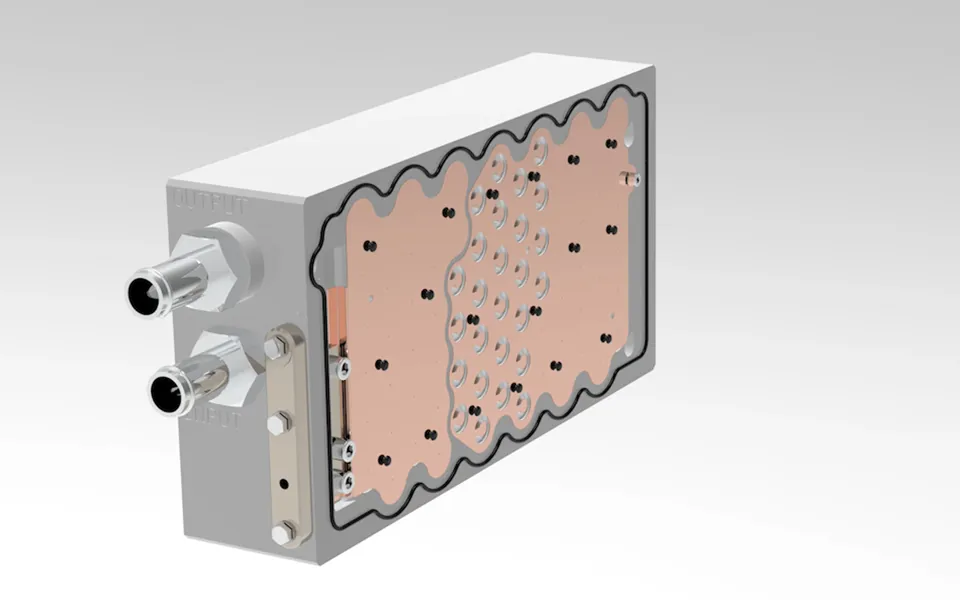

Battery cooling technology

Read project

Immersion cooled battery technology for electric vehicles

Read project

Unlocking sustainable economic growth with modern electricity rate design

Read insightBattery design, simulation and development testing for a safe and sustainable future

Book a consultationRicardo has extensive battery engineering, design and development experience in the field of hybrid and electric vehicles. We develop battery pack and energy storage solutions across a range of capabilities ranging from applying new chemistries and formats, to designing and building prototype packs and supporting our clients through full production programmes.

Our whole-vehicle hybrid and electrification design and development experience gives us the contextual insight we need to develop optimum vehicle battery solutions.

Our battery teams utilise the latest tools and techniques to ensure robust design and development and are integrated with our vehicle engineering team to ensure optimal mechanical, structural, and thermal design, maximising volumetric and gravimetric density, be it for a power or energy dense application.

Our battery and energy storage services are tailored to the requirements of our clients. This ensures that the solutions we develop align with the specifications of their product portfolio.

We work with clients across multiple sectors, from the transportation industry to the energy and industrial sectors.

We work with original equipment manufacturers (OEMs) and tier 1 suppliers to develop and deliver battery and energy solutions to help to decarbonise product portfolios.

- Requirement analysis and vehicle simulation

- Chemistry and cell format selection

- Cell characterisation and life cycle modelling

- CFD modelling, thermal modelling and thermal system design

- Mechanical design and integration

- Electrical design - electronics, battery management systems (BMS), contactors, fusing and creepage and clearances

- Functional safety

- Crash simulation

- Failure mode and affects analysis (FMEA) and design validation planning

- Testing in house or working with partners Ricardo is familiar with global test and development requirements for validating global battery pack

The third generation of Ricardo’s Universal battery management system (BMS) has been developed to allow rapid prototyping of new automotive battery packs with focus on systems requiring certification to ISO 26262. Without hardware changes it can be software configured for different cell chemistries, cell and module configurations. Key features include:

- Supports 12V-1000V and compatible with 12V and 24V systems

- Supports four CAN interfaces including CAN-FD

- Adaptable battery SoC estimation strategies

- High charge/discharge rate capable (15C/30C)

- High performance 32-bit processing cores allowing execution of advanced algorithms

- Robust, reliable automotive grade hardware suitable for serial production projects

- Adaptable to wide range of chemistry, pack design and storage medium

- -40°C to +85°C operating range

Ricardo’s immersion cooled battery technology is being applied to applications in passenger vehicles, aircraft and commercial vehicles to name a few. Our innovative battery packs are shown to improve peak charge rate by 40% whilst delivering up to 48% higher peak power density.

Immersion cooling has a number of benefits including increased pack longevity with up to a 22% longer battery lifetime.

Benefit from longer range in a smaller package with Ricardo’s capability to fit more than 1000 cells in a module, yielding more energy in the same volume. Our battery technology is capable of lowering pack material cost and in turn vehicle cost.

As a result of Ricardo's experience in immersion cooling technology, clients benefit from rapid development times. Ricardo can develop an immersion cooled module from clean sheet in just 9 months, depending on requirements.

The EU’s Sustainable Batteries Regulation will have wide-reaching impacts on many organisations. Ricardo's experts can help. From clarifying policy, through to creating a strategy and then implementing compliance solutions, we provide expert guidance to clients around the globe.

Batteries and energy storage Resources